Another Lean Road Map training has wrapped up. And in its wake are more WMCO wood manufacturers with wider eyes to see waste for what it is, and how to go about reducing it.

Over two days, Brad Cairns, Quantum Lean in partnership with Sepp Gmeiner, Lignum Consulting provided online training teaching the foundation of Lean manufacturing with a plethora of videos, examples, first-hand experience, step guides, quizzes, and more.

The interactive training provided a platform attendees could keep at pace and enjoy the training along the way. The event explored important lean principles, concepts, and ways companies can cultivate a lean culture of productivity and continuous improvements. Roundtable discussion capped off each day with attendees sharing their personal experiences on production & Lean concepts learned.

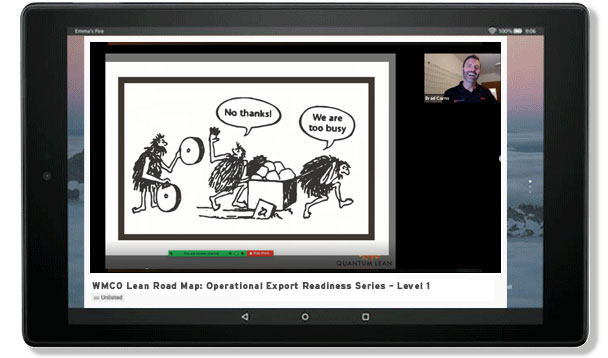

Like anything, before you get yourself where you want to go, it is important to know where you start – in the case of lean, it is the state of mind. Sometimes it’s a matter of how you think about waste, time, and space. When you reorient a perspective, it aids in removing roadblocks to throughput, uncovering hidden costs, productivity improvements, and much more.

How long does it take to complete a lean journey as a company? For those companies that are familiar with lean, they know this is a trick question. The journey never stops in the reduction and elimination of waste through lean thinking, it only gets better.

Comments are closed.