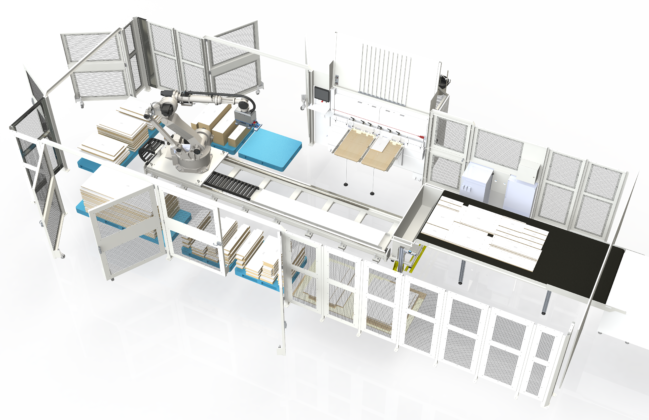

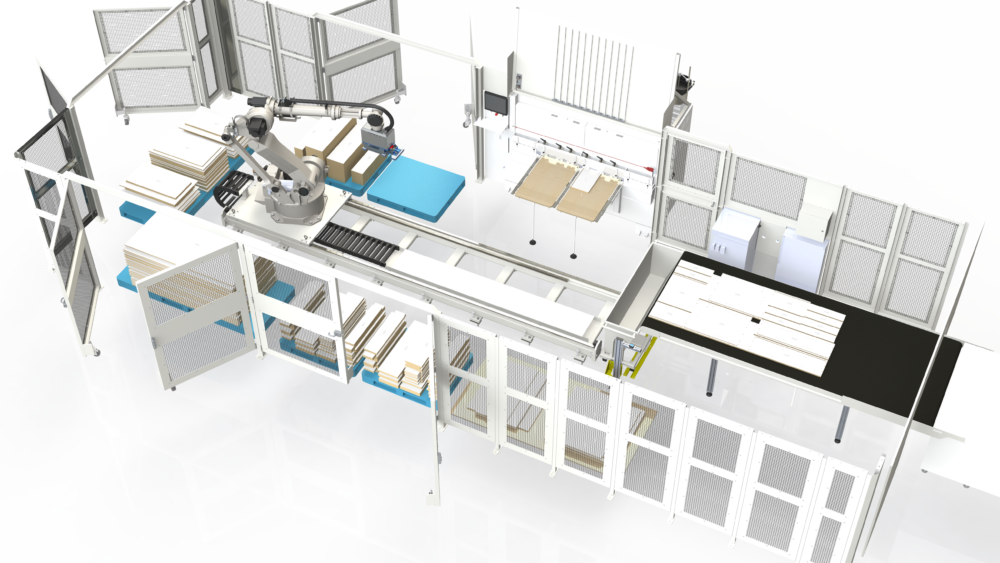

Edge Automation has created this Robotic Nest Unloading solution and is placed at the outfeed conveyor of a nesting CNC machine equipped with automatic labelling. This cell has a wide range of benefits, and sorting abilities, to automate the cabinet sorting process, maximize efficiency, decrease waste, and reduce the overall production footprint of multiple processes. It combines CNC offloading with doweling and part sorting, increasing the efficiency of all of these processes, and providing processed panels at the end.

The cell has the ability to sort parts based on part family, by kitchen, as well as by common dimensions. It has the capability to handle a vast assortment of panels, with dimensions as small as 3” wide, and as large as 84” long. The Robot is also placed on a linear 7th axis rail system to allow for maximum sorting capabilities while keeping the cell footprint within the facility minimal.

We provide a rigorous maintenance schedule, and unmatched customer service – if this is your first venture into automating cabinet production, you’re not alone! We think of every robotic sort cell installation as the beginning of a relationship with automation, and we’re here to support you every step of the way.

Comments are closed.